U.S. and European Missile Production: Meeting the Demand of High-Intensity Conflict

Introduction

The Pentagon is grappling with a mounting challenge in missile production. Rising global instability, combined with the prospect of high-intensity conflict, has forced the Department of Defense to urge industry leaders to significantly expand output. In some cases, manufacturers have been asked to double or even quadruple production. The newly established Munitions Acceleration Council was created to facilitate closer coordination between the Pentagon and industry. This reflects a recognition that current production levels are insufficient to meet operational requirements should a major conflict break out.

Demand Outpacing Supply

War games and recent operational experiences demonstrate the scale of the problem. A 2023 report by the Center for Strategic and International Studies (CSIS) revealed that in a simulated conflict with China, the United States could expend over 5,000 long-range missiles in only three weeks. This figure far exceeds existing industrial capacity. The issue is not theoretical. During the “Twelve Day War” in defense of Israel against Iranian missile salvos, the United States used a significant portion of its interceptor stockpiles, creating strain on future readiness. Simultaneously, ongoing support for Ukraine, coupled with missions in Yemen and Iran, has increased demand for advanced munitions across multiple theaters. This tempo of use is unsustainable under current production levels and represents a strategic vulnerability.

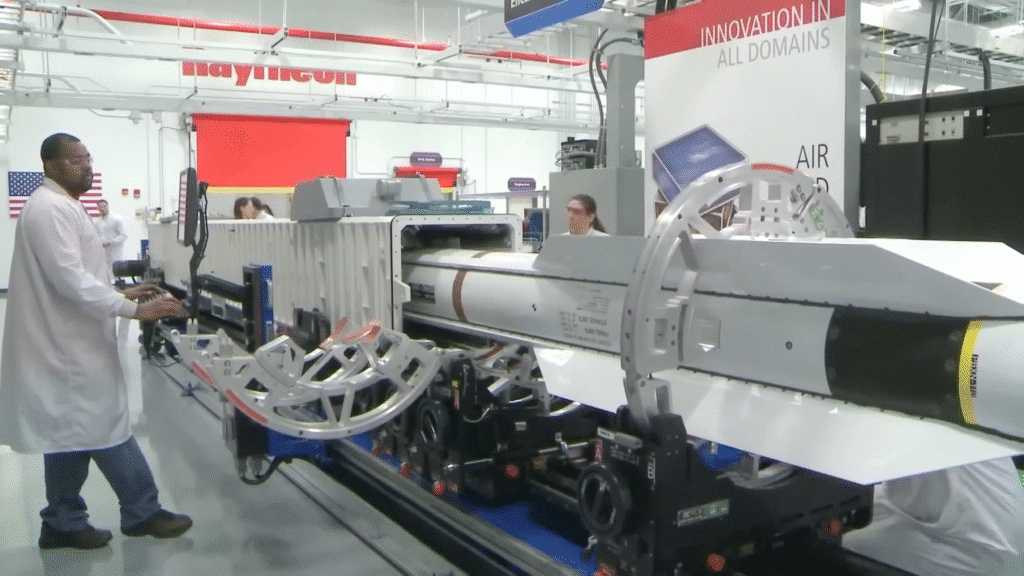

Industry Response and Bottlenecks

Large defense contractors, including Lockheed Martin, Raytheon, and Northrop Grumman, have responded by expanding facilities and securing major new contracts. Production of systems such as the Patriot PAC-3 interceptor and Tomahawk cruise missile has been prioritized. Yet scaling production to wartime levels remains complex. The most severe bottlenecks are concentrated in a few critical areas. Solid rocket motors are produced by a small number of qualified suppliers and require long testing and certification cycles. Guidance systems and specialized microelectronics remain in short supply, constrained by limited fabrication facilities and competition with the commercial electronics sector. Propellants and other energetic materials rely on specialized chemical supply chains, many of which lack redundancy. Even where funding is available, the industry struggles with workforce shortages, facility expansion, and the availability of test ranges and infrastructure. Compounding these challenges are uncertainties in congressional appropriations. Without long-term purchase guarantees, companies are reluctant to invest heavily in permanent expansions that may become idle if funding dries up.

The Department of Defense has sought to mitigate these issues by engaging new entrants into the supply chain. Startups such as Ursa Major, X-Bow Systems, Anduril, and Firehawk are developing novel propulsion systems and solid rocket motor technologies to reduce reliance on a handful of established suppliers. This represents a promising diversification strategy, although the timeline to qualify and integrate new suppliers remains long. Industry consolidation over decades has left the missile sector with limited elasticity, and building resilience will take sustained investment.

Representative U.S. and European Missile Systems

The following table highlights a set of representative U.S. and European missile systems currently in service. These missiles cover the most significant categories, from air-to-air interceptors to long-range cruise missiles and tactical ballistic systems. It includes manufacturer, country of origin, approximate unit cost, operational range, type, launch modes, and primary use. The following table demonstrates the breadth of current inventories and underscores the reliance on high-cost systems whose replacement rate lags far behind potential wartime usage

Visualizing the Production Gap

A graphic representation of the missile production challenge would show a steep curve of demand in wartime scenarios quickly eclipsing current production capacity and stockpiles. At the top of the curve lies a projection of more than 5,000 long-range missiles expended in less than a month. Beneath it sits a much flatter line depicting annual production capacity. Connecting the two is a series of bottlenecks, solid rocket motors, microelectronics, propellants, and workforce constraints, which form a choke point between demand and supply. This gap illustrates why even modest regional conflicts can deplete inventories faster than they can be replenished, leaving the United States and its allies vulnerable in protracted engagements.

Strategic Recommendations

The path forward requires both near-term surge capacity and long-term structural investment. Multi-year contracts with guaranteed purchase volumes are essential to provide industry with the confidence to invest in expanded facilities and workforce. Supply chain diversification is critical, particularly in solid rocket motors, propellants, and radiation-hardened microelectronics. Accelerated qualification of new suppliers should be paired with streamlined certification and testing processes to reduce delays without compromising safety. At the same time, investment in lower-cost, modular strike options will help build affordable mass, complementing high-end precision munitions with systems that can be produced at scale. Finally, closer NATO and European Union cooperation, including pooled procurement and harmonized production lines, could increase aggregate resilience and prevent fragmentation of industrial capacity across allies.

Conclusion

The challenge facing the United States and Europe is not merely about producing more missiles. It is about transforming the industrial base to withstand the demands of modern high-intensity conflict. War games and real-world crises have exposed the vulnerability of current stockpiles and production levels. While defense primes are expanding and startups are entering the supply chain, bottlenecks in critical materials and budgetary processes remain serious obstacles. Without bold investment and procurement reform, the West risks falling short in the next major conflict. Addressing this challenge now will determine whether the U.S. and its allies can maintain credible deterrence and operational resilience in the years ahead.