Trump's New Tariffs: Industries and Businesses Poised to Benefit

What happened?

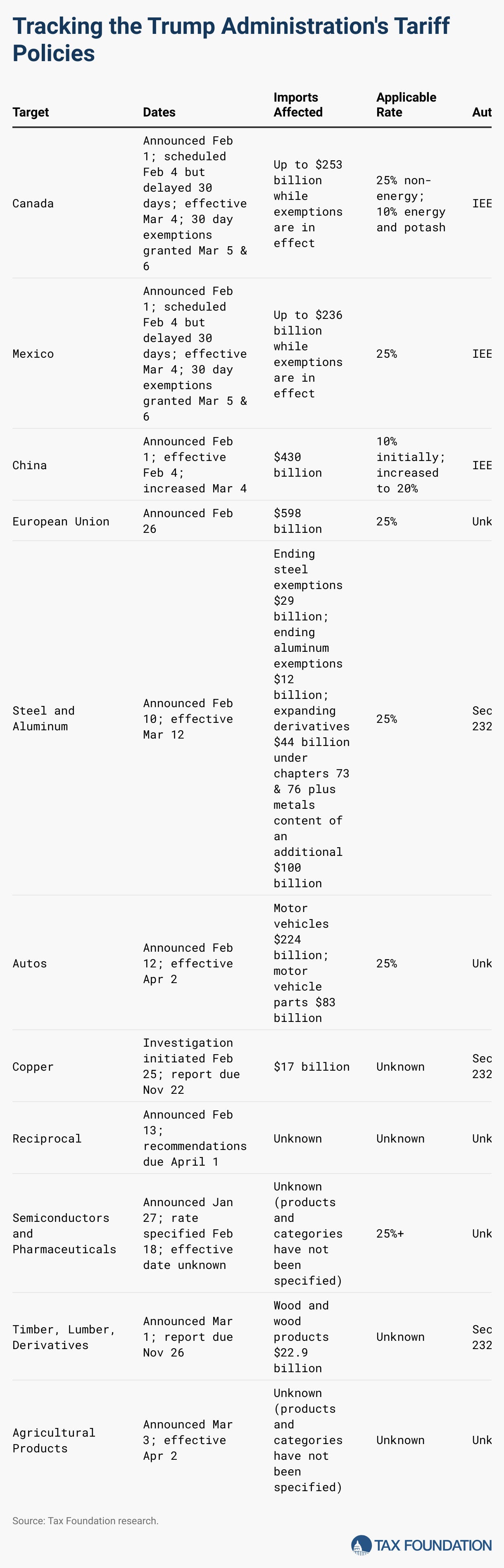

Since taking office on January 20, President Trump has introduced several policies and executive orders. On his first day in office, he issued the “America First Trade Policy,” which launched an investigation into unfair trade practices, expected to conclude on April 1. A key component of this investigation, "Unfair and Unbalanced Trade," targets countries with significant annual trade deficits in goods, potentially subjecting them to country-specific tariffs. This includes several European Union nations (e.g., Germany, Ireland, and Italy), Asian jurisdictions (e.g., Vietnam, Japan, and Taiwan), and other global trade partners. A review of unfair trade practices by other countries and a consultation with respect to the United States-Mexico-Canada Agreement (USMCA) also are key components of the investigation.

Additionally, on February 13, President Trump introduced the Fair and Reciprocal Plan, designed to evaluate and impose reciprocal tariffs on countries that enforce higher duties/tariffs on US goods, including through a value-added tax or other non-tariff barriers. The European Union, India, and Japan have been identified as potential targets due to their tariff policies on American products.

Both the America First Trade Policy and the Fair and Reciprocal Plan are expected to have their investigations completed by April 1 with potential new tariffs as soon as April 2.

President Trump's recent wave of tariffs has created significant shifts in global trade dynamics, imposing substantial costs on imported goods while simultaneously creating powerful incentives for companies to relocate operations to the United States. With tariffs now covering over $1.4 trillion in imports—compared to approximately $380 billion during his first administration—these policies represent a strategic effort to revitalize American manufacturing and create domestic jobs. This analysis examines which industries are best positioned to benefit from these tariffs, which specific businesses are likely to relocate, and what opportunities exist for small business owners and manufacturers in this rapidly evolving landscape.

Industries Primed for Domestic Relocation

Automotive and Transportation Equipment Manufacturing

The automotive sector stands as perhaps the most significantly impacted industry under the new tariff regime. With the United States having imported more than $86 billion worth of motor vehicles and $63 billion in auto parts from Mexico last year alone, manufacturers face substantial cost increases under the 25% tariff on Mexican goods. This creates compelling incentives for production relocation, particularly for companies with established Mexican operations.

Nissan has already signaled that President Trump's tariffs could push the company to move production from Mexico to the United States. The automotive supply chain's tight integration across North American borders makes this industry particularly vulnerable to tariffs but also creates clear opportunities for companies willing to shift operations northward. The extensive network of automotive manufacturing—from parts suppliers to assembly plants—means relocations could create cascading effects throughout the industry.

Steel and Aluminum Production

The 25% global tariff on steel and aluminum products that took effect on March 12, 2025, creates strong incentives for domestic production in these critical industries. Unlike previous iterations of these tariffs, the current policy eliminates all country exemptions and expands the list of derivative products, making it nearly impossible for manufacturers to avoid these costs through international sourcing.

The Steel Manufacturers Association and the Aluminum Association have praised these measures, with Robert Simon, CEO of JSW Steel USA, specifically highlighting them as initiatives that will "flood the U.S. with jobs as trading partners move their industries to U.S. soil to avoid tariffs." For businesses in metal-intensive industries, establishing or expanding U.S. production facilities may prove more economical than absorbing these substantial tariff costs long-term.

Electronics and Semiconductor Manufacturing

With plans for tariffs of "25 percent and higher" on semiconductors and computer chips, the technology manufacturing sector faces significant pressure to relocate. Nvidia has already indicated readiness to navigate these trade challenges, with CEO Jensen Huang announcing plans to relocate some chip production to the United States in response to the potential 25% tariffs on imported chips.

The semiconductor industry's strategic importance to national security and economic competitiveness makes it a particularly appealing target for reshoring initiatives. Companies that establish domestic production capabilities not only avoid tariffs but may also position themselves favorably for government contracts and partnerships in an increasingly protectionist environment.

Pharmaceutical and Medical Products

The pharmaceutical and life sciences industries have been specifically targeted for tariffs under the Trump administration's trade policies. These sectors, which have increasingly globalized their supply chains in recent decades, now face strong incentives to localize production of medications and medical devices. The substantial margins in pharmaceutical products make these industries better positioned than many others to absorb the initial costs of relocation while maintaining profitability.

Opportunities for Small Business Owners and Manufacturers

Domestic Supply Chain Integration

As larger manufacturers relocate to the United States, significant opportunities emerge for small businesses to integrate into domestic supply chains. Small manufacturers producing components, materials, or specialized parts can position themselves as reliable domestic suppliers, capitalizing on both the tariff advantage and the logistical benefits of proximity to major manufacturers.

Small business owners that currently import products must now consider continuing with their current foreign suppliers versus locating alternative suppliers within the United States. This reconsideration opens markets for domestic producers who can offer competitive alternatives to imported goods, even if at slightly higher price points when the tariff impact is factored in.

Specialized Manufacturing Services

Small businesses offering specialized manufacturing services—including precision machining, custom fabrication, specialized finishing, or quality testing—stand to benefit substantially as larger operations relocate. These specialized service providers can fill crucial gaps in the manufacturing ecosystem without requiring the massive capital investments needed for full-scale production facilities.

Reshoring Consulting and Support Services

The complexity of relocating manufacturing operations creates demand for specialized consulting services. Small businesses with expertise in logistics, supply chain management, regulatory compliance, or workforce development can offer valuable services to companies navigating the reshoring process. This represents a significant opportunity for service-oriented small businesses to support the broader manufacturing relocation trend.

Niche Product Manufacturing

Smaller manufacturers focusing on niche products with higher margins may find themselves newly competitive against imported alternatives. Products requiring specialized knowledge, customization, or rapid delivery are particularly well-suited for domestic production and may benefit disproportionately from the protective effect of tariffs on competing imports.

Challenges and Strategic Considerations

Financial and Capital Requirements

Establishing new manufacturing operations in the United States requires substantial upfront investment. For many companies, particularly small and medium-sized businesses, this represents a significant barrier to reshoring. The government offers incentives such as grants, tax credits, and other financial support for businesses to manufacture products in the U.S., but navigating these programs requires careful planning and expertise.

Small businesses operate on thinner margins than larger corporations and may struggle to absorb the temporary costs of transition. Those considering relocation must evaluate not only the tariff impact but also the comprehensive economics of U.S.-based manufacturing, including higher labor costs, regulatory compliance, and energy expenses.

Policy Uncertainty and Long-Term Planning

One of the most significant challenges for businesses considering relocation is policy uncertainty. Manufacturing facilities represent decades-long investments, yet tariff policies can change with administrations. As Alcoa CEO Bill Oplinger noted, "We make decisions around aluminum production that have a horizon of 20 to 40 years. We would not be making an investment in the United States based on a tariff structure that could be in place for a much shorter period of time."

This uncertainty creates a strategic dilemma for businesses. Moving too quickly could expose them to significant risk if policies change, while moving too slowly could mean missing the competitive opportunity presented by the current tariff structure.

Supply Chain Realignment

For businesses heavily dependent on existing global supply chains, reshoring requires comprehensive supply chain realignment. Small businesses that have built their operations around imported components must identify domestic alternatives or potentially bring additional production steps in-house. This transition period can create temporary disruptions and inefficiencies that must be carefully managed.

Strategic Opportunities for Success

Hybrid Manufacturing Models

Rather than attempting complete re-shoring immediately, businesses can adopt hybrid models that gradually increase domestic content while maintaining some international sourcing. This approach allows companies to benefit from tariff avoidance on finished goods while spreading the capital investment over a longer period.

Automation and Technology Investment

Higher U.S. labor costs can be partially offset through investments in automation and advanced manufacturing technologies. Small manufacturers that invest in these capabilities can achieve competitive cost structures while benefiting from the quality control and intellectual property protection advantages of domestic production.

Strategic Partnerships and Collaborations

Small businesses can form strategic partnerships with other domestic manufacturers to share resources, distribute investment costs, and create more complete domestic supply chains. These collaborative approaches can make re-shoring more economically viable while creating resilient local manufacturing ecosystems.

Conclusion

The tariff policies implemented by the Trump administration in 2025 have created powerful economic incentives for manufacturing relocation to the United States. While the automotive, steel and aluminum, semiconductor, and pharmaceutical industries appear most immediately impacted, opportunities exist across the manufacturing spectrum. Small business owners and manufacturers who strategically position themselves—whether as domestic suppliers, specialized service providers, or niche product manufacturers—stand to benefit significantly from this shifting landscape.

The path forward requires careful evaluation of both the opportunities and challenges. Financial considerations, policy uncertainty, and supply chain complexity create substantial hurdles, but businesses that develop thoughtful strategies for navigating these challenges may find themselves well-positioned in an increasingly domestic-focused manufacturing economy. As President Trump has stated, "The biggest win is if they move into our country and produce jobs. That's a bigger win than the tariffs themselves.”