Space Forge Secures $30 Million Series A Funding

The demand for semiconductors is increasing due to AI and electric vehicle advancements, but silicon has limitations. Space Forge, a U.K. startup, secured £22.6 million in Series A funding to manufacture wafer materials in space, where unique conditions offer opportunities for enhanced materials. The Cardiff-headquartered company develops reusable satellites designed for the manufacturing of super materials in space for return to Earth to be used to help aid the transition to low carbon technologies.

The NATO Innovation Fund led the funding round, with additional support from World Fund, the National Security Strategic Investment Fund (NSSIF), and the British Business Bank through its Regional Angels program. Other investors included Innovation Investment Capital Limited Partnership, Gaingels, SpaceVC, Unruly, Helium Three, Stellar and TypeOne, and London Technology Club.

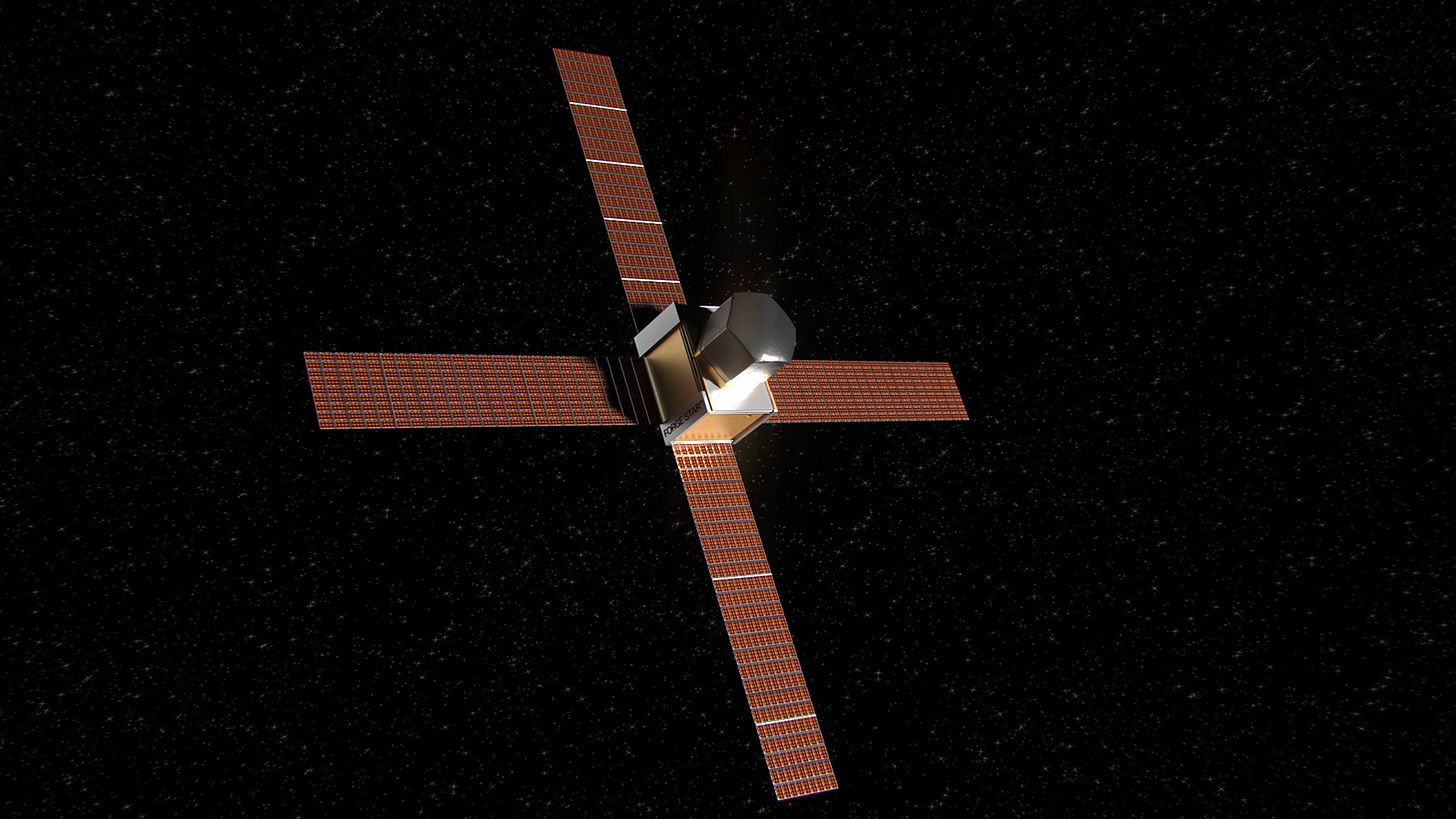

The funding will expedite the development of the company’s advanced returnable manufacturing satellite, ForgeStar-2, and facilitate Space Forge’s inaugural in-orbit demonstration mission, ForgeStar-1, scheduled for launch this year. The objective of the ForgeStar-1 mission is to validate the company's returnable and re-launchable platform for manufacturing high-performance semiconductor materials in space.

CEO Joshua Western stated that research over five decades confirms the feasibility of manufacturing chips in orbit, which could enhance technologies such as quantum computing and defense systems.

Space Forge relies on existing space providers for launches, focusing on chip manufacturing and space return technologies. Adapting to extreme temperatures and microgravity presents challenges, but engineering bridges the gap between innovation and commercial viability.

Space Forge focuses on new return technology. It developed Pridwen, a heat shield inspired by King Arthur, and Fielder, a floating net for catching satellites to ensure a soft water landing. These initiatives are supported by the U.K. Space Agency and European Space Agency, of which the U.K. remains a member despite Brexit.

Establishing a return infrastructure across Europe is among Space Forge’s goals. This week, the company opened an office in Portugal on the Azores island of Santa Maria, suitable for satellite returns and an important step toward scaling industrial operations in Europe.

The commoditization of return and launch technologies has enabled the rise of in-space manufacturing startups, with applications extending to drug discovery and telecom hardware. However, their viability remains dependent on reducing costs or finding clients willing to pay a premium.

Shifting geopolitical dynamics could aid Space Forge in securing more clients. Western and his co-founder Andrew Bacon previously worked at Thales Alenia Space, a joint venture between Thales and Leonardo. Broader concerns about reliance on Taiwanese semiconductors are driving demand for resilient, homegrown supplies of next-generation supermaterials. “We urgently need sustainable, homegrown production of advanced materials for future computing,” Daria Saharova, a General Partner at climate tech VC firm, World Fund, stated.

World Fund, who co-led Space Forge’s seed round and participated in its Series A, bought into Space Forge’s positioning as a “carbon negative technology” combating climate change. However, emissions savings have yet to be validated at scale and depend on commercial adoption to offset each mission.

Space Forge, however, has yet to complete its first mission. Its initial attempt was unsuccessful when Virgin Orbit’s rocket experienced an anomaly during a 2023 launch, resulting in the loss of its entire payload, including Space Forge’s ForgeStar-0 satellite.

With new funding, Space Forge is accelerating the development of its latest spacecraft and preparing for the launch of ForgeStar-1 later this year. The mission, named “The Forge Awakens,” was announced in early May.

Related:

Space Forge Launches EU Expansion with New Portugal office

Space Forge Sees LEO as Key to Strengthening US Chip Independence