Eavor Prepares to Bring First-of-a-Kind Geothermal Project Online

Eavor, an innovative geothermal startup from Canada, has announced major progress at its near-complete project in Germany. The company reported that new drilling techniques have drastically reduced drilling times and led to technological advancements, important steps toward making clean energy extraction from underground sources more affordable.

In October, Eavor, released two years of drilling data from its Geretsried flagship site. These results support Eavor’s efforts to install advanced “closed-loop” geothermal systems in deeper and hotter regions than what traditional projects can reach. Jeanine Vany, co-founder and Executive Vice President of Corporate Affairs, noted this technical breakthrough proves geothermal energy could see cost reductions similar to those achieved by wind, solar, and unconventional shale energy.

Eavor belongs to a fast-growing field focused on expanding geothermal energy generation beyond classic locations like California’s Salton Sea or Iceland’s volcanic zones. The company, along with others such as Fervo Energy, Sage Geosystems, and XGS Energy, is adapting oil and gas industry methods to work under challenging, high-pressure conditions deep below ground.

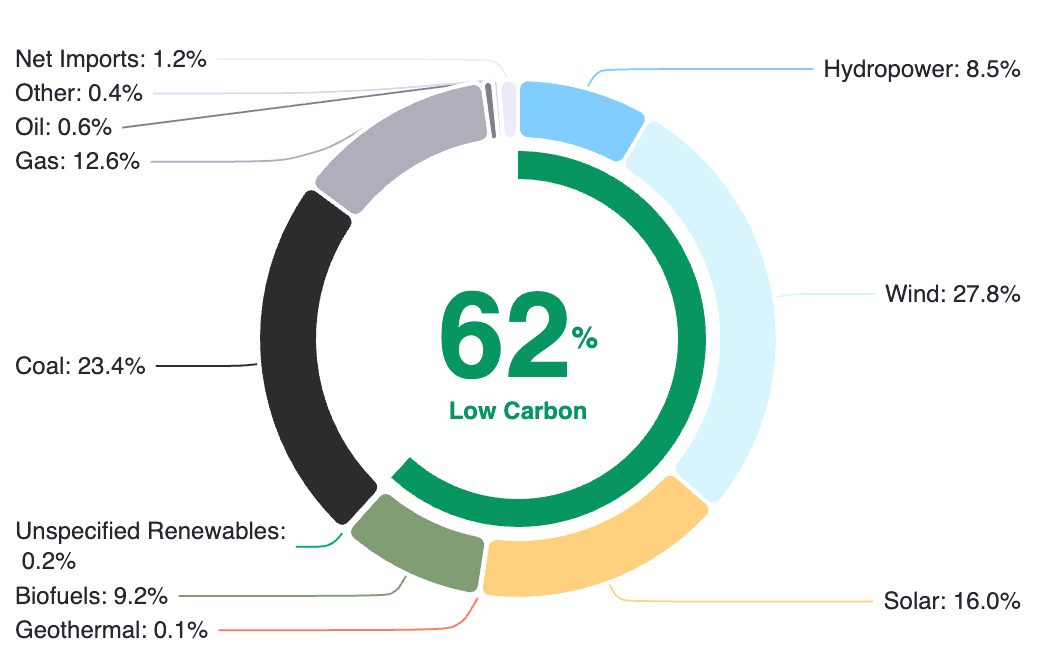

Industry leaders hope these advances will deliver dependable, clean power and heat nearly anywhere worldwide, positioning geothermal as a constant companion to renewable sources like solar and wind, which are not always available. Still, these pioneering technologies are just beginning to be deployed in practical settings.

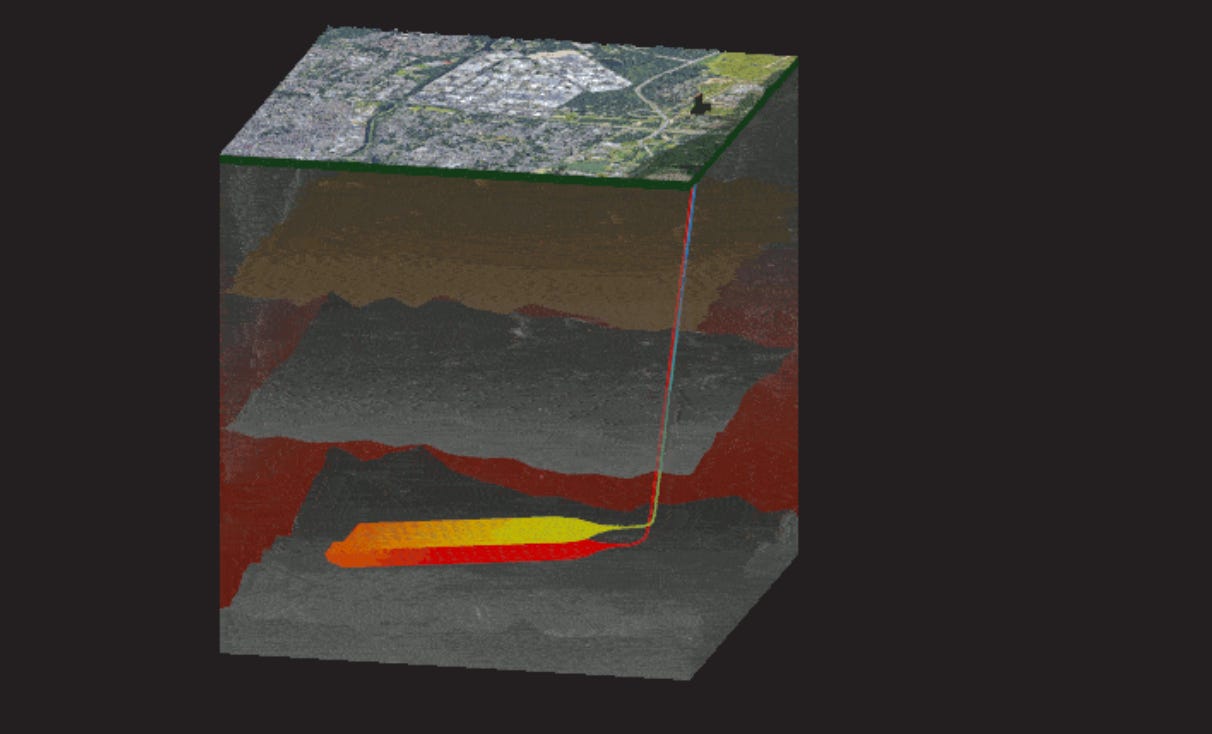

Eavor commenced drilling operations in Geretsried in July 2023, following a €107 million grant from the European Union’s Innovation Fund. For its initial “loop,” the firm drilled two vertical wells extending almost 2.8 miles deep, complemented by twelve horizontal laterals, each approximately 1.8 miles in length. These wells are connected underground and sealed to function similarly to radiators: circulating water within the loop absorbs geothermal heat from surrounding rock and transports it to the surface.

With the first of four planned loops nearing completion, construction of the second loop is scheduled for March 2026. Upon full operation, the system will provide 8.2 megawatts of electricity to the regional grid and 64 MW of district heating to nearby communities, operating flexibly to adjust output according to seasonal demand.

Eavor’s latest report details substantial challenges in drilling the initial eight lateral wells, which required over 100 days, a considerable expenditure given daily rig rental costs of approximately $100,000. Nevertheless, improved techniques and equipment modifications reduced drilling time for the remaining four wells by 50%.

Notably, the introduction of insulated drill pipe technology enabled more effective cooling of drilling tools in high-temperature environments, enhancing drilling rates. Equipment adjustments also tripled the lifespan of drill bits, minimizing operational downtime. These advancements are expected to boost thermal-energy output per loop by roughly 35%.

The Geretsried project is poised to become the world’s first commercial system of its type upon commencing power generation later this year. Alternative next-generation methods, such as enhanced geothermal systems (EGS) being developed by Fervo in Utah and Nevada, are simultaneously scaling up.

EGS techniques involve fracturing subsurface rock and injecting fluids to create artificial reservoirs, which extract geothermal heat to generate steam. While EGS can deliver higher efficiency, it may increase the risk of seismic activity or groundwater disruption, though experts note well-managed projects can mitigate these concerns. Closed-loop systems, favored in jurisdictions where fracking is prohibited, continue to advance independently.

Closed-loop designs however also present certain limitations. The pipes can constrain heat transfer between rock and circulating fluids, thereby limiting total system energy output. Achieving sufficiently high fluid temperatures and flow rates remains an economic challenge for closed-loop developers. Nonetheless, Eavor’s modeling indicates its technology aligns with European “levelized cost of heat” benchmarks, which range from $50 to $100 per megawatt-hour thermal, depending on market volatility. After completing the initial four loops, Eavor anticipates reaching the lower end of the learning curve, underscoring the strategic purpose of the Geretsried project.